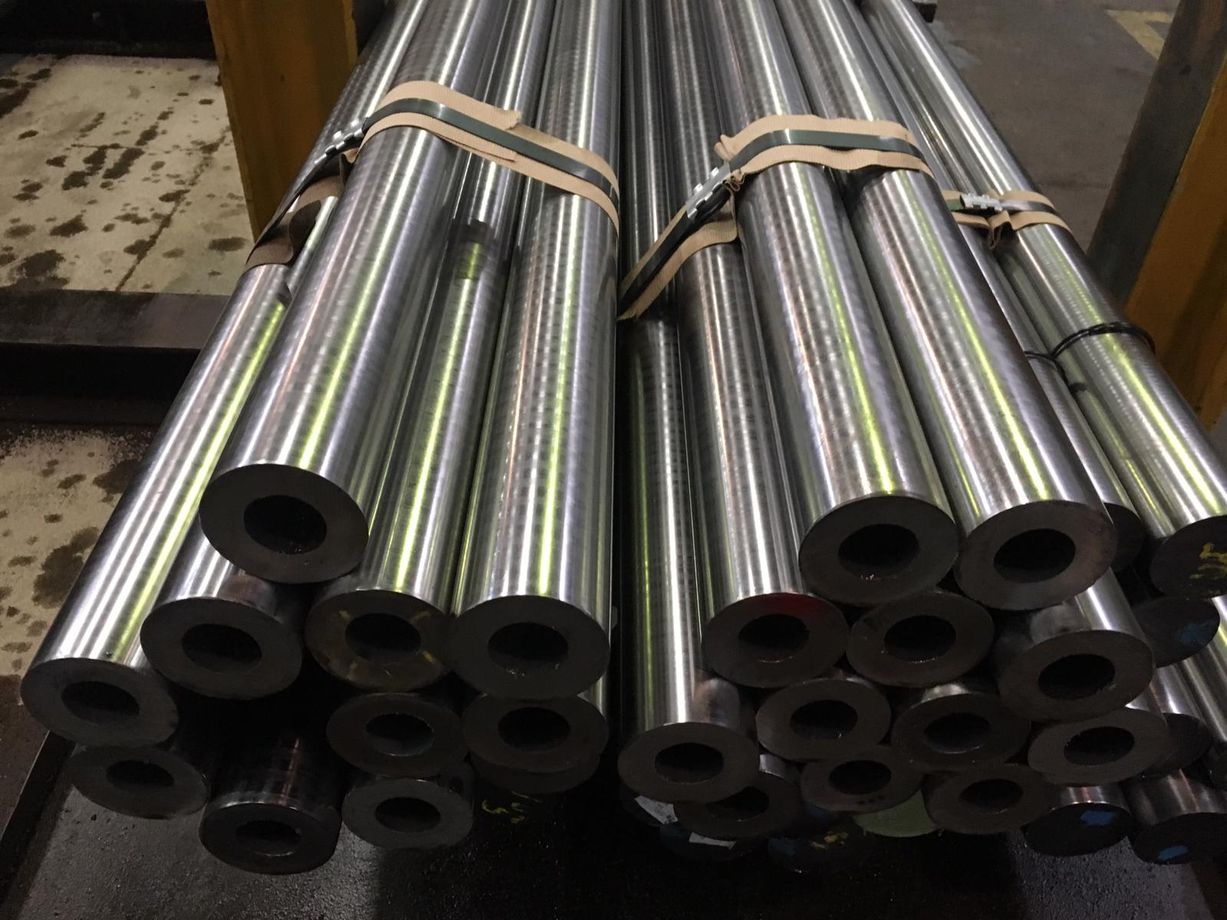

Roughed and ground material

Thanks to continuous investments, such as the purchase of three grinding machines, and primarily thanks to the new warehouse dedicated to the storage of ground material for immediate sale, I.T.R. Srl is even more efficient and prompt in its services to its customers.

Contact

From stock we guarantee the range of round ground steels:

from round 20 to round 100 in C45 with tolerances h6 and h7

from round 40 to round 100 in 39NiCrMo3 quenched and tempered (+ QT) with tolerances h6 and h7

Contact us for information regarding the NEW WAREHOUSE.

Ground and roughed(+SL ground material)

The purpose of rough grinding is to remove most of the stock and to reduce shape defects, while the intent of finishing grinding is to bring the piece to the desired size and to ensure a controlled and homogeneous roughness.

Grinding is carried out using an abrasive wheel for the removal of very small shavings and has the purpose of eliminating all surface imperfections and / or mechanical marks.

Consequently, the product has an excellent precision in terms of size, shape and surface finish.

The advantage of the grinding process (from peeled round) is that the physical and mechanical properties of the steel remain unaltered (as hot rolled).

According to the various needs, the ground round bars can be previously heat treated (for example annealing, normalization, quench and tempering), chamfered, sawn or controlled by non-destructive tests such as Circograph and / or US.

The range of ground products:

- from 08 mm to 110 mm as contract manufacturing

- from 38 mm to 110 mm diameter on consignment

Standard tolerances: h6 - h7

Other tolerances by request

Minimum length: 3.00 meters

Maximum length: 9.20 meters

Possibility of fixed lengths on request.

Bar/bar or bundle packaging

Use of rings/ bubble wrap/ jute